BBC Top Gear expert Paul Horrell explores the benefits of hydrogen-powered cars, and how they could help to shape driving in the coming years

In the not-so-distant past, hydrogen fuel-cell cars were the future – a solid bet to win ‘the race’ for zero-emission cars, because a decade ago everyone thought they could go further and refuel faster than battery-electric cars. But now that practical battery cars are here, where are the fuel-cells? While still a rarity, many still think they’ll be a crucial part of the future mix. Here’s why.

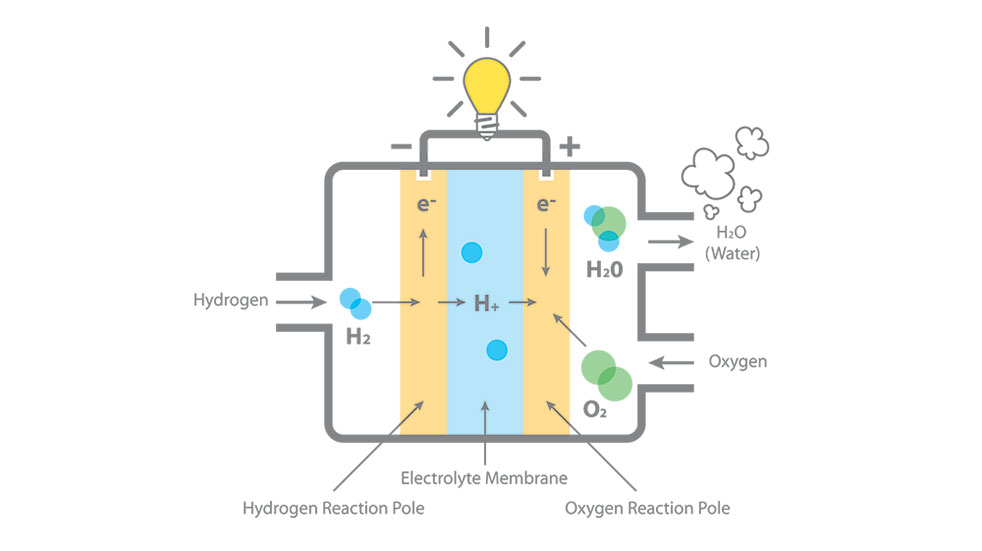

A fuel-cell vehicle (FCV) is a type of electric vehicle (EV) because it’s driven by an electric motor. But instead of storing energy as electricity in a big battery, it stores it as hydrogen in a tank. The fuel cell itself combines hydrogen with oxygen taken from the air, generating electricity in the process. All that’s emitted from the tailpipe is pure water vapour. So to drive, an FCV – such as the Toyota Mirai or the Hyundai Nexo – is just like a battery EV, only with a little extra noise from the pumps that push the gases around.

Right now, FCVs are expensive at £65,000–£70,000. This is partly due to high-cost materials in the stack membranes (see diagram below), and also the tanks that store the hydrogen gas at immensely high pressures. But mass-manufacture always lowers cost. The chicken-and-egg issue is that sales remain low. Just a few hundred of these cars ply Britain’s roads. The reason isn’t so much their price but the refuelling. Only a handful of hydrogen stations are open in the whole of Britain.

The benefits of fuel-cell vehicles

But look at their advantages. You can refuel them in five minutes or so, whereas recharging a battery takes at least an hour, even with a rapid charger. That could matter even more to people who live in a flat and can’t recharge at home. Also, the fuel cell and tank are much lighter than a battery big enough for several hundred miles.

In the case of trucks or buses, this weight difference becomes even more crucial, because every kilo of propulsion system means one less kilo of payload. Also, many commercial vehicles operate out of a depot, which could have its own hydrogen pump. That’s why hydrogen buses aren’t a particularly rare sight.

Hyundai has developed a fuel-cell truck of 34 tonnes gross weight and it can do 300 miles between refills, which take just seven minutes. It’s deploying a fleet of them in Switzerland. That nation has abundant renewable energy, used in this case to produce hydrogen by electrolysis – essentially reversing the fuel cell. Under the Swiss tax regime, it makes the trucks as cheap to operate as diesel vehicles, and they don’t pollute. Hyundai sees this as a critical pathway towards priming the hydrogen infrastructure. And it drives down the cost of fuel cells and hydrogen tanks by increasing production numbers.

• Read our feature on the 50 greatest British drives, as voted for by you

Others disagree. “I don’t believe there will be a parallel infrastructure [of hydrogen and electric chargers],” states BMW’s senior vice president in charge of product. “Battery vehicles will be an industry focus.” But then his company doesn’t make trucks.

Even so, BMW is hedging its bets, having a fuel-cell partnership agreement with Toyota, another industry leader in the technology. Hyundai is also lending its fuel-cell knowledge to Audi as a way to encourage uptake. Meanwhile, Riversimple, a tiny firm in Wales, has developed a local-journey fuel-cell car that improves efficiency through its lightness and incentivises a long life through its pay-for-use business model.

The environmental impact of fuel-cell vehicles

The green case for fuel cells is complex, but here’s a summary. At the moment, a lot of hydrogen is produced from natural gas, using reforming equipment at the filling station. This produces CO2. But according to the US Union of Concerned Scientists, about the same amount of CO2 per km is emitted from driving an FCV on this hydrogen as from driving an EV on electricity that’s also generated from natural gas burned at a power station. Hydrogen from biomass can even be ‘carbon-negative’, by preventing methane emission.

• Read our round-up of the best new cars to buy this summer

That said, the transition to renewable grid electricity is happening rapidly. But it’s not the whole supply, and it’s fair to point out that fuel cells aren’t especially efficient. If you take 1kWh of electricity to electrolyse water, then put the electrolysed hydrogen into an FCV, you can drive about 1.2 miles. Put that 1kWh into a battery car and you’ll get three miles out of it.

Yet things are never that simple. For an offshore wind farm or solar array in an unpopulated area, it’s expensive to get the electricity to where the battery cars are. Electrolysing hydrogen at the power generation site then piping it to the cars can be cheaper than an electricity cable. Gas pipelines from the North Sea will eventually be redundant, but could be repurposed to carry hydrogen generated alongside North Sea wind farms.

Watch our motoring expert Dan Read as he answers questions on electric vehicles

So FCVs can be complementary to battery EVs, because hydrogen works well as a long-distance energy carrier. It’s also an energy storage medium, very handy for the times when the wind isn’t blowing and the sun isn’t shining.

Also, the manufacturing footprint of FCVs is smaller than for EVs with big batteries; they use fewer minerals and less energy. And as a bonus, FCVs cleanse the atmosphere of CO and NOx particulates as they drive along – it happens because they have to filter the air that flows through the stack, or else it gets poisoned.

• Read our great electric car odyssey from Milton Keynes to Dundee

“It’s unhelpful to say it’s about electric cars or fuel-cell cars,” says Mike Dolman of low-carbon analysis consultancy Element Energy. “It’s stupid to rule out any green technology.” Hyundai and Toyota agree. Hyundai has said it will build more fuel-cell cars to complement its Nexo, and Toyota has already outlined its next-generation Mirai.

But no one can predict a date when mass adoption of FCVs will come. Most commentators believe they’ll follow on from the use of fuel cells for ships, or stationary energy generation. In Japan, Toyota has announced plans for a city designed to try out new forms of robotics, AI and autonomous vehicles. This city will get most of its electricity from fuel cells. A beacon project like that will surely push the technology along.

How fuel-cell vehicles work

Illustration: Jasper Rietman

The fuel cell’s heart is a stack of special membranes. Hydrogen is pumped across one face of the membranes and air across the other. The nuclei of hydrogen atoms are tiny, being just one proton, so they permeate through the membrane. On the other side they combine with the oxygen in the air to form H₂O – pure water. This leaves too many electrons on the hydrogen side and too few on the oxygen side. The membranes are connected by wiring, allowing the electrons to rebalance, and this generates electricity.

Fuel-cell vehicles in numbers

7

The current number of publicly accessible hydrogen refuelling stations in the UK. A few more are on private land or just for captive fleets. An industry plan calls for 65 by 2030. Still not many.

4.2hp per litre

The power density of the Toyota fuel-cell stacks. So a 150HP stack would be just 35 litres in size – smaller than an engine of equivalent power. The electric motor is compact, too.

50

London cab service Green Tomato runs this many Toyota Mirai FCVs – the biggest Mirai fleet in Europe. The firm says running costs match a Prius. The first 25 have now covered 1,000,000 miles.

200,000

Manufacturing this number of FCVs per year will push prices down to parity with comparable battery-electric vehicles, says Hyundai – a leader in fuel-cell research but also a battery car maker.

5 minutes

On average, the time taken to refuel an FCV with hydrogen. Even rapid-charge electric cars take well over an hour to get the same range of about 300 miles.

14

The factor by which hydrogen is lighter than air. This means that if any hydrogen leaks, it will quickly disperse upward – unlike petrol vapour, which hovers invisibly near the ground.

400

There are, or shortly will be, this many fuel-cell buses in service across Europe. If you’re in London, look out for the world’s first double-decker fuel-cell buses on routes 7 and 245. Ding ding!

500,000

The planned number of fuel-cell vehicles a year to be built by the Hyundai group. It also expects to supply an additional 200,000 fuel-cell stacks for use outside the automotive industry.

483.4 miles

The record distance, without refuelling, held by a fuel-cell production car: a Hyundai Nexo, driven across France by round-the-world solar pilot Bertrand Piccard. It still had 30 miles' range at the finish.

All photos: Getty Images